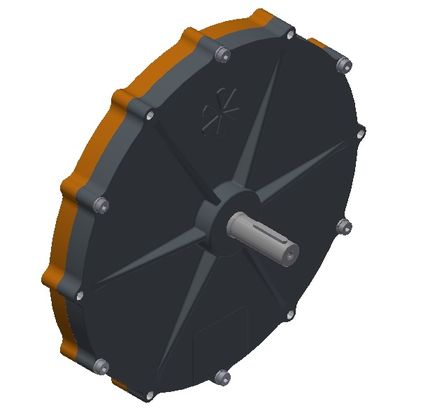

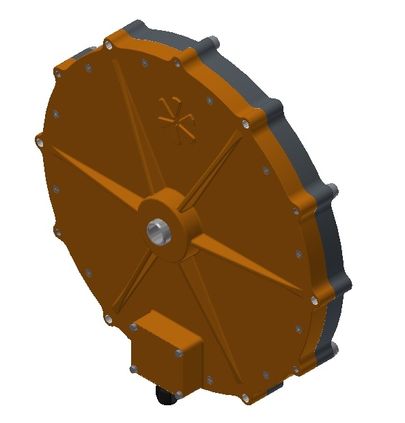

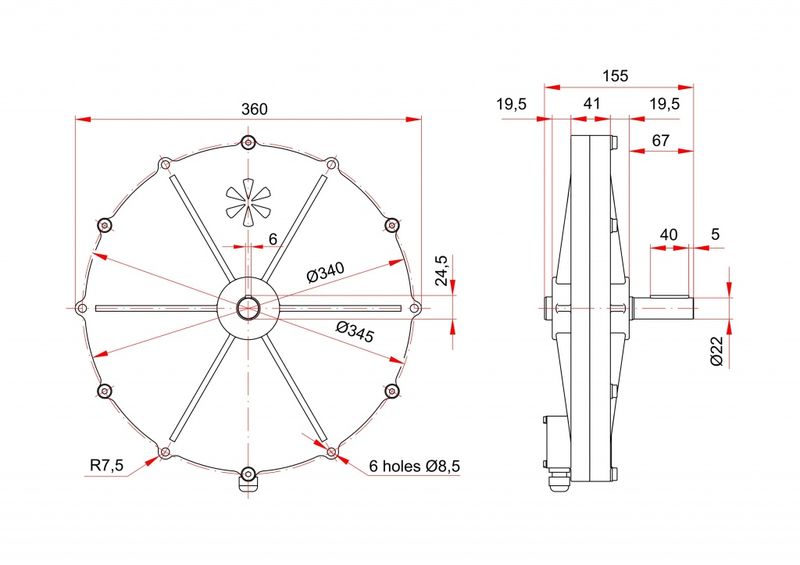

LOW-SPEED GENERATOR

AW-I 3P

Product Code: ALT00011

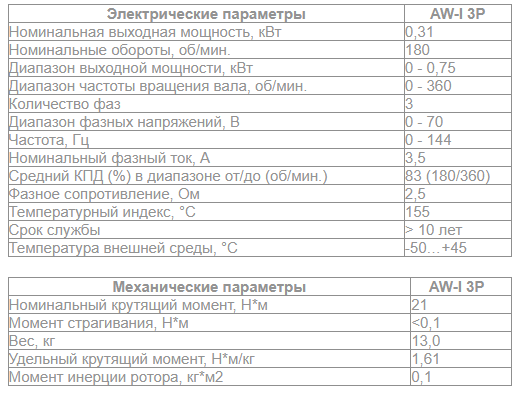

Rating Plate

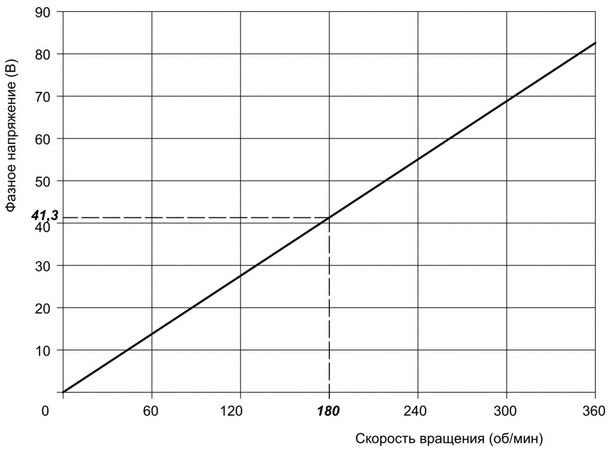

Rating rotational speed = 180 RPM

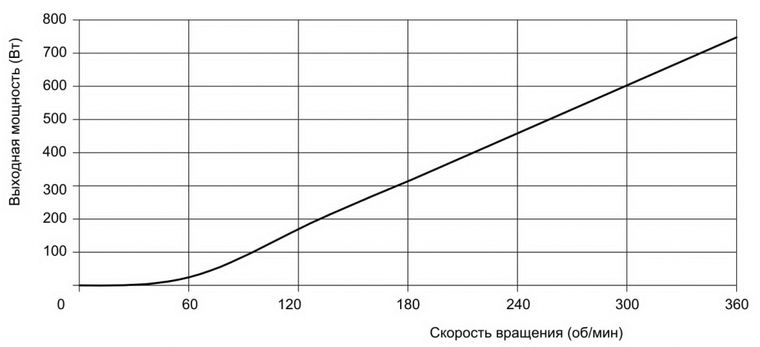

Rated power = 310 W

Rated phase current = 3.5 A

Number of phases = 3

Phase voltage = AC 30 V

Phase = 3, weight = 13 kg

Rating rotational speed = 180 RPM

Rated power = 310 W

Rated phase current = 3.5 A

Number of phases = 3

Phase voltage = AC 30 V

Phase = 3, weight = 13 kg

Description

+

Specification

+

The

The