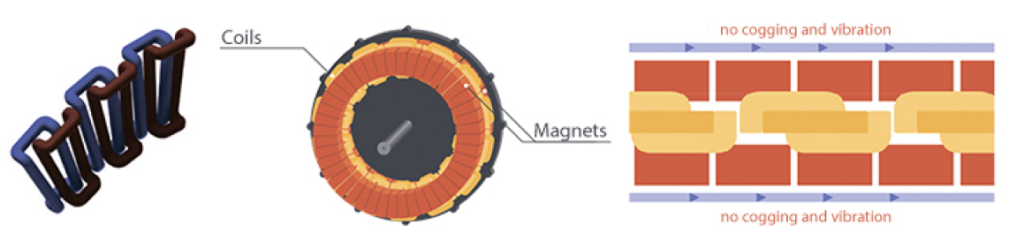

The classic configuration of coreless stator coils enables stator windings to cover the gap between rotor plates and magnets no more than 45%! This means that in this case more than half of the gap is not being used. In addition, if the low-power alternator construction has a radial configuration of the stator-rotor system, the alternators with power output up to several hundreds of watts will weigh not much less than kilowatt models of similar design.

Due to our special crossed saddle coils based on the patented CCSC® Technology, stator windings provide a coverage of more than 80% of the gap between rotor plates. The record-breaking efficiency of covering the gap with stator windings CCSC® makes it possible to design coreless alternators with exceptional power density. As a result, the AW alternators with CCSC® and axial configuration are 2-3 times lighter compared to conventional counterparts! The axial configuration of alternators with permanent magnets in combination with multi-pole CCSC® stators provides one more important feature of generators for the use in the wind power industry – that is an ultra-low nominal rotation speed.

The proportional covering of the working gap with stator windings using the CCSC® technology almost without any empty space, the absence of a ferromagnetic core in the gap, as well as special location and configuration of the permanent magnets on the rotor discs ensure the complete absence of cogging effects. This is particularly important for vertical wind-wheels which should start rotation at minimum wind speed.

Classic generators usually have a 1- or 3-phase electrical AC output. An important feature of generators designed on the basis of CCSC® technology is a 2-phase electrical output with phase shifts by 90°. Therefore, in order to provide DC output of 2-phase models of generators, we recommend using 2 rectifiers consistently connected to the customer’s equipment.